Accurate

Using ball screws instead of hydraulics makes the Coastone press brakes very, very accurate.

Electric

Our machines are pretty silent. Maybe you’d like to hear something else than a roaring machine?

Green

All electric means no oil. No need to pollute the environment. Do your part and save the planet.

About

All of our machines are built in Finland, home to Europe’s higher quality machine exports. They are all electric, servo-driven and built to run for decades in most demanding environments. They will last from father to son.

Our Machines

C-Series Press Brakes

The C-Series press brakes are our solution for bending all of your smaller parts. They operate with one or two ball screws and provide accurate results easily and reliably. As standard, they have user-friendly Cone TC programming that even the newest operators can run expertly on their first day.

The C9 is the successor of the loved Cone900. It features a single ball screw which makes it an affordable investment but still capable of bending the majority of the smaller parts. Its small size allows the operator to sit while working, which ensures a high level of ergonomics.

Coastone’s signature servo driven ball screws make the machine accurate but also very environmental friendly – in average use the C9 consumes less than 1,5 kW. The lack of hydraulic oil eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The C9’s taller brother provides a bigger daylight compared to the standard machine. It allows more versatile bending capabilities and tooling options. Besides the added height the C9X is much alike the C9. It allows the operator to sit while working, ensuring a high level of ergonomics.

Coastone’s signature servo driven ball screws make the machine accurate but also very environmental friendly – in average use the C9X consumes less than 1,5 kW. The lack of hydraulic oil eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The big brother of the beloved C9 provides an extra punch if you just need some more power. With 2 ball screws and servos instead of one, the C12 doubles the available bending strength. Also it has a longer bending length which allows you to bend also wider parts.

Coastone’s signature servo driven ball screws make the machine accurate but also very environmental friendly. The lack of hydraulic oil eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

C12’s taller brother provides a bigger daylight compared to the standard machine. It allows more versatile bending capabilities and tooling options. Besides the additional height the C12X is much alike the standard C12. It features 2 ball screws and a maximum bending length of 1300 mm.

Coastone’s signature servo driven ball screws make the machine accurate but also very environmental friendly. The lack of hydraulic oil eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The biggest machine of the C-Series features two servo driven ball screws. Its bending length allows you to bend a big variety of parts while still maintaining low operating costs. The C15 is a versatile machine and a lucrative alternative for a bigger press brake.

Coastone’s signature servo driven ball screws make the machine accurate but also very environmental friendly. The lack of hydraulic oil eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The tallest C-Series machine, the C15X, provides a bigger daylight compared to the standard machine. It allows more versatile bending capabilities and tooling options. Besides the additional height the C15X is much alike the standard C15. It features 2 ball screws and a maximum bending length of 1550 mm.

Coastone’s signature servo driven ball screws make the machine accurate but also very environmental friendly. The lack of hydraulic oil eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

- Wila (US style) tooling

- Promecam (European style) tooling

- Lazersafe safety device

- Tilting front table

- Z1-Z2 axis

- Cone TC15 control with 15” screen

G-Series Press Brakes

The G-Series is our press brake line for a bit bigger bending needs.

They are the perfect answer when you require an accurate and constant angle over long bends.

The G20 features an O-frame just like all the G-Series press brakes. It deflects less than a conventional C-frame while still remaining lighter. The G20 has three servo driven ball screws which crown and bend simultaneously. Due to the servos’ high accuracy, the upper beam can be CNC deflected to “follow” the lower beam seamlessly. This is the unique system that gives you a great bending result. This is CoastOne’s unique direct crowning.

In addition to servo technology’s superior kinematic, it also saves the environment. The lack of hydraulic oil also eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The G25 features an O-frame just like all the G-Series press brakes. It deflects less than a conventional C-frame while still remaining lighter. The G25 has four servo driven ball screws which crown and bend simultaneously. Due to the servos’ high accuracy, the upper beam can be CNC deflected to “follow” the lower beam seamlessly. This is the unique system that gives you a great bending result. This is CoastOne’s unique direct crowning.

In addition to servo technology’s superior kinematic, it also saves the environment. The lack of hydraulic oil also eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The G30 features an O-frame just like all the G-Series press brakes. It deflects less than a conventional C-frame while still remaining lighter. The G30 has five servo driven ball screws which crown and bend simultaneously. Due to the servos’ high accuracy, the upper beam can be CNC deflected to “follow” the lower beam seamlessly. This is the unique system that gives you a great bending result. This is CoastOne’s unique direct crowning.

In addition to servo technology’s superior kinematic, it also saves the environment. The lack of hydraulic oil also eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

The G40 features an O-frame just like all the G-Series press brakes. It deflects less than a conventional C-frame while still remaining lighter. The G40 has six servo driven ball screws which crown and bend simultaneously. Due to the servos’ high accuracy, the upper beam can be CNC deflected to “follow” the lower beam seamlessly. This is the unique system that gives you a great bending result. This is CoastOne’s unique direct crowning.

In addition to servo technology’s superior kinematic, it also saves the environment. The lack of hydraulic oil also eliminates expensive oil changes, spare parts, valves and maintenance expenses common to hydraulic press brakes.

- Wila (US style) tooling

- Promecam (European style) tooling

- Lazersafe safety device

- Cnc-controlled sheet followers (2 pcs)

- Z1-Z2 axis

- Cone TC15 control with 15” screen

Bull Series

Bull series is solution when hight tonnage is needed with superior accuracy.

High precison O-frame with taylor made ball screws makes Bull-series superior solution for high accuracy bending works. Bull is optimal solution with small foot print and high tonnage. Bull is optimal solution with small foot print and high tonnage.

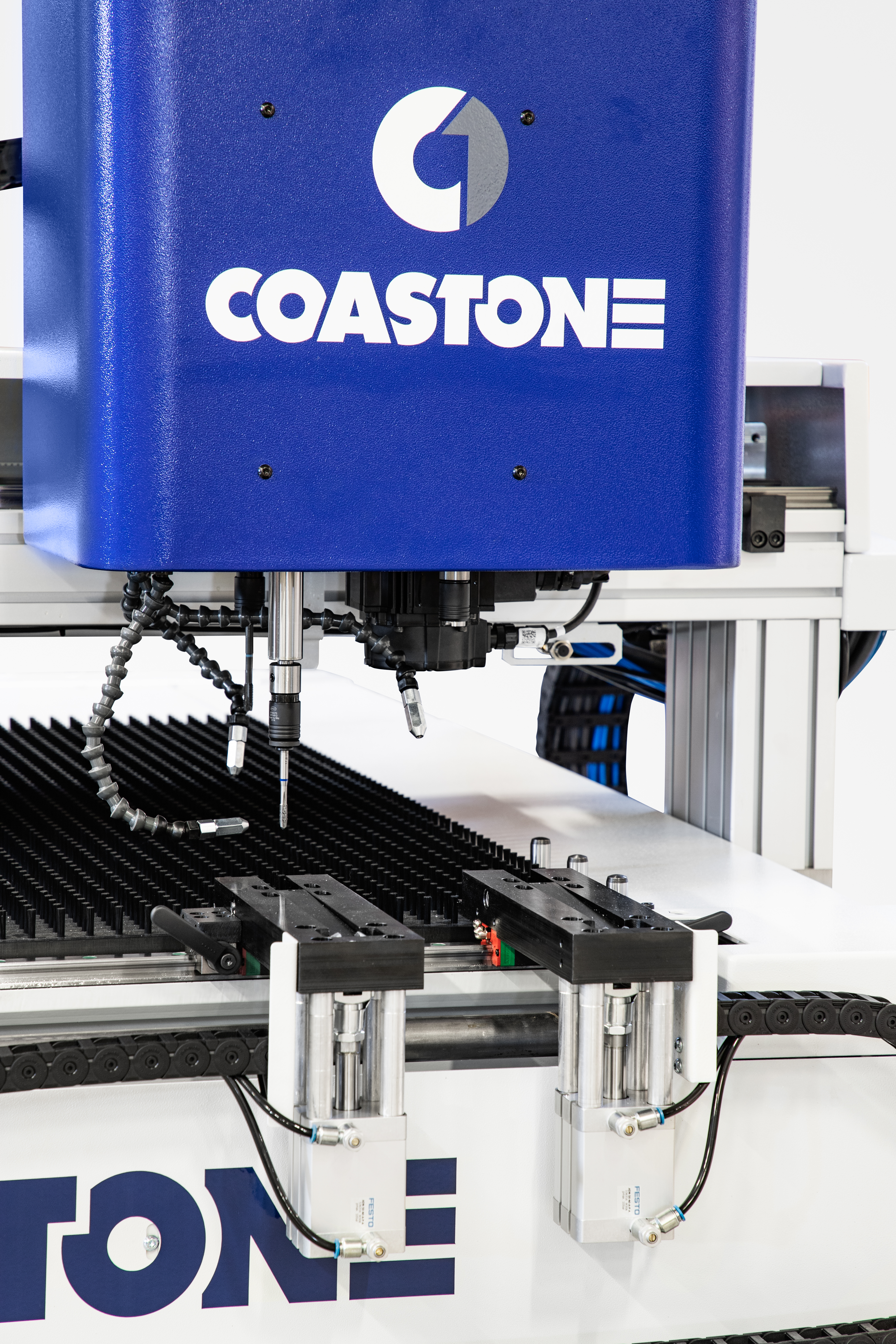

Multitapper tapping and counter sinking Machines

MultiTapper is an efficient and accurate way to complete your threads and

counter sinks with high accuracy and speed without opetating mistakes.

MultiTapper MT1212 is bridge type machine with rigid die anvil with combination of tapping and counter sink machining.

MutltiTapper MT1212 complete all your tapping needs with high speed and guaranteed accuracy.

Multitapper MT1212 is efficient investment to avoid hustle and problems with manual tapping and counter sinking.

Solve your problems and human errors of manual tapping. Solution is MultiTapper MT1212.

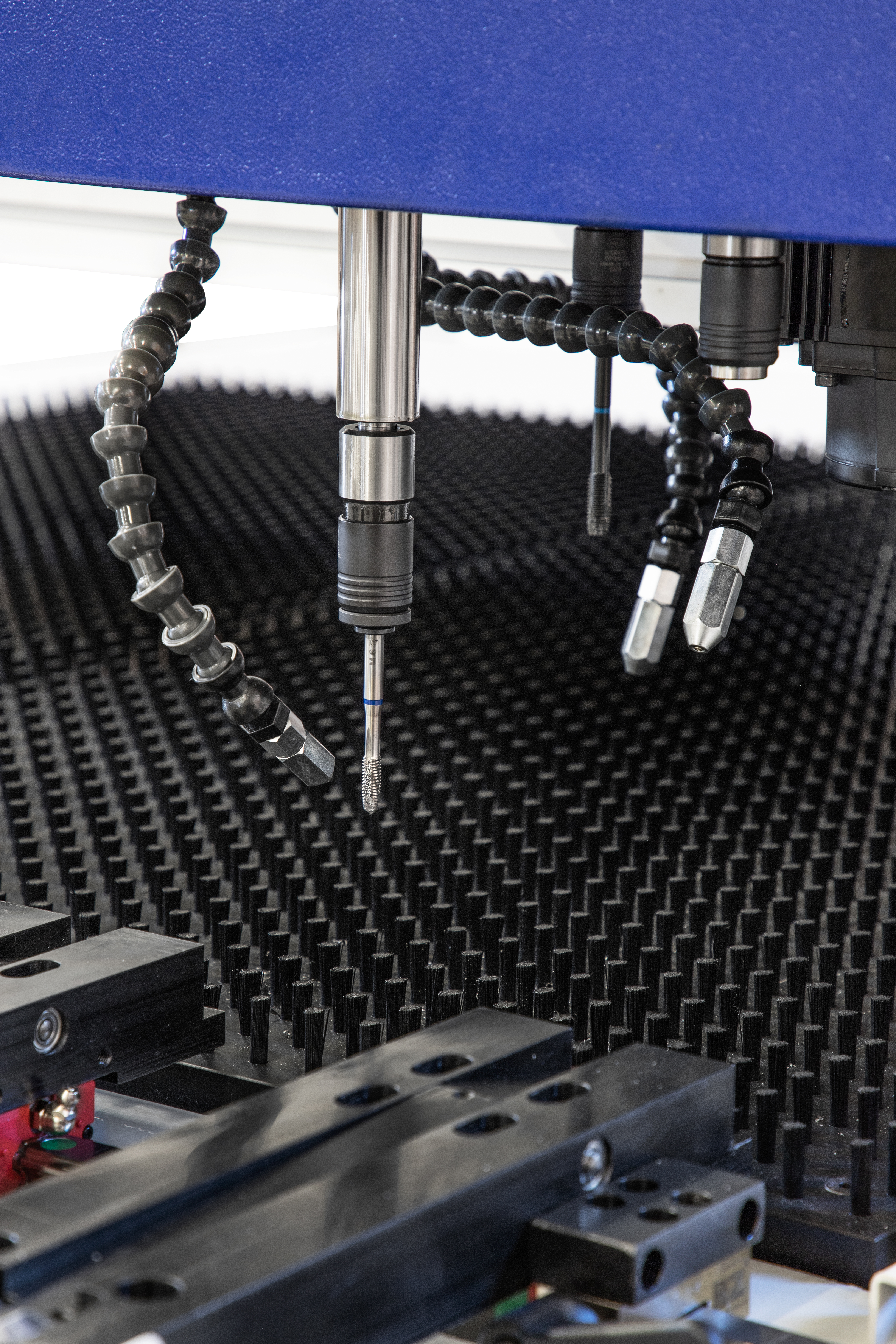

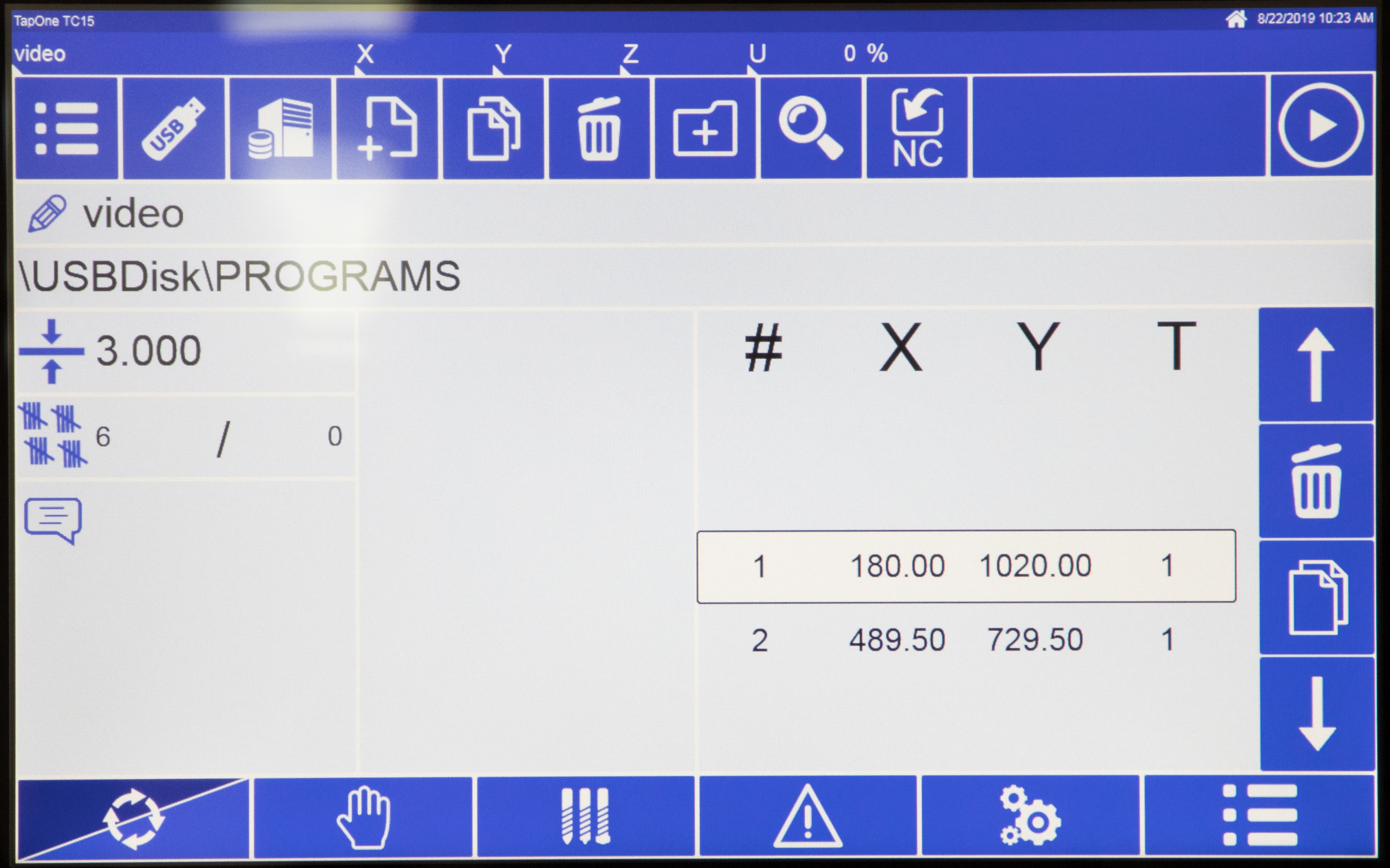

TapOne Tapping Machines

TapOne is an efficient alternative between the manual way and the integrated way.

They are specialized 4-axis CNC machines, to make threads in a reliable and efficiant way.

Is a full range machine, able to load full size big format sheet on the table (1250 x 1250 mm).

It has 3 spindels for different threads; each one with own programmable speed and micro lubrication. Big parts, small parts, big threads (max M10), small threads, thin parts, thick parts (up to 50 kg). Controlled by Touch Screen. That is TapOne.

Pressone inserting machines

Modern technology for fastener insertions. Powered by servo motor driven ball screws.

Pressone inserting machine is a compact and powerful package.

TC 12 touch screen control on swing arm for easy operation.

It has unlimited program capacity and tooling wizard database.

Operator friendly and powerfull TC 12 control. Easy to use and also allows modifications according customer demands. With programmable insertion speed for soft and fragile parts.

Safety sensors mounted on ram head ensures fast and safe production cycle.

Pressone inserting machine is a compact and powerful package.

TC 12 touch screen control on swing arm for easy operation.

It has unlimited program capacity and tooling wizard database.

Operator friendly and powerfull TC 12 control. Easy to use and also allows modifications according customer demands. With programmable insertion speed for soft and fragile parts.

Safety sensors mounted on ram head ensures fast and safe production cycle.

oUR tEAM

JUKKA HAKALA

jukka.hakala

@coastone.fi

Sales

JANNE rAITTILA

Finland / Baltic States / Russia

janne.raittila

@coastone.fi

+358 50 5537 098

R&D

SAMI MURHAKORPI

sami.murhakorpi

@coastone.fi

Business Administrator

TARJA RIITAKORPI

tarja.riitakorpi

@coastone.fi

+358 50 5767 946

VESA ERKKILÄ

Finland

vesa.erkkila

@coastone.fi

+358 44 2561 800

JUHA VUORELA

juha.vuorela

@coastone.fi

Production Manager & Quality Control

JUKKA LAHKO

jukka.lahko

@coastone.fi

+358 50 3017 658

PHILIPPE ARCHER

Southern Europe

philippe.archer

@coastone.fi

+33 75 0687 395

Service Coordinator

LAURI VÄNTÄNEN

lauri.vantanen

@coastone.fi

+358 50 4764 308

SASCHA DREXLER

Germany / Austria / Switzerland

sascha.drexler

@coastone.fi

+49 152 5486 1009

International

SERVICE

service

@coastone.fi

+358 50 5501 883

ALEXANDER LINK

Toolings

alexander.link

@coastone.fi

+39 333 8441 620

CONTACT

If you would like us to contact you, please fill the form below.

OFFICE

Tuottajantie 27 A1

60100 Seinäjoki

Finland

FACTORY

Hallitie 4

60100 Seinäjoki

Finland

Kalliokoskentie 12

62200 Kauhava

Finland